Twin City Vibration & Balance llc.

We are a veteran-owned business and your trusted partner for industrial fan services including repair, troubleshooting, testing, alignment and inspection services. Our mission is to provide affordable best in class services and deliver maximum results, while putting the needs of our clients first.

You are priority one

Services We Offer

Current services Twin City Vibration & Balance offers are industrial fan services including repair, troubleshooting, testing, alignment and inspection services. offer.

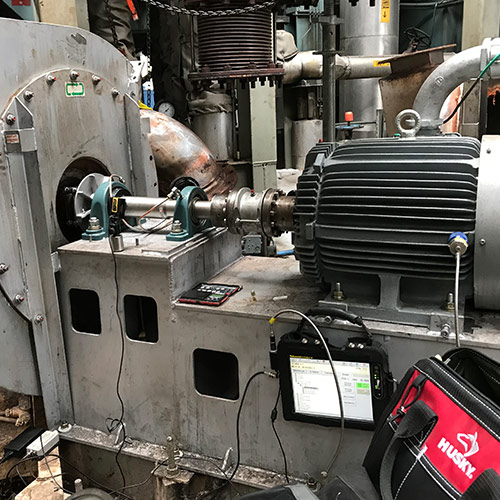

Precision Laser Alignment:

In 99% of all circumstances a precision alignment between a driver and driven component are essential for low vibration levels. Misalignment can lead to increased vibration levels, increased wear or all rotating components, increased power consumption, and possibly catastrophic failure of the system.

Installation Inspections:

A good running machine starts with a good installation on a solid base. Reviewing and correcting a fan installation from the anchor bolts to the flex connectors helps ensure a solid foundation on which a piece of equipment will run for years to come. This is best accomplished just before the fan is placed in its final location before being grouted into place.

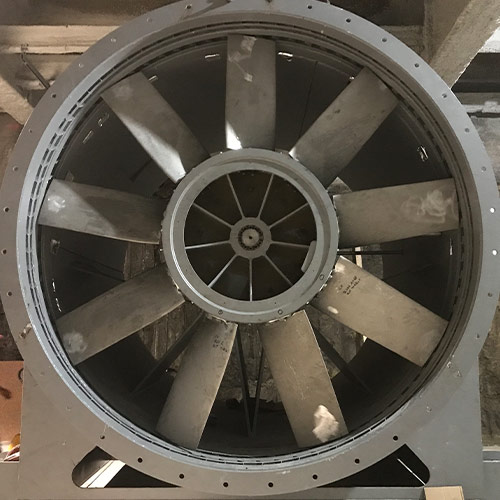

Balancing:

Twin City Vibration & Balance can effectively and quickly balance most rotating equipment on site. When we are asked to balance a machine, the entire unit is checked top to bottom for underlying conditions such as mechanical looseness, belt or drive misalignment, belt tensions, and bearing condition and secondary faults.

Troubleshooting:

Many issues are invisible to the naked eye or just not common knowledge. This is where an experienced rotating equipment professional can be a great asset. Using specialized equipment and years of experience we can track down vibration sources, troubleshoot performance issues or improve the reliability of an existing system.

Route Collection:

Route collection is perhaps the best bang for your buck in the vibration world. You have a list of equipment that you have concerns on. We collect vibration data on the motor, fan, and pump bearings as they are going through their daily operations. We then analyze the data and submit the report to you with the equipment status per ISO 20816 and maintenance recommendations with supporting data.

Motion Amplification:

A video that shows the direction and amplitude of vibration in a system. Think of that, a video of a system before and after corrections have been made. These exportable videos visually convey the issue even the most mechanically inept in an easy to understand format.

Farm Services:

Grain and bin driers are some heavily abused equipment. They run 24/7 for months on end during harvest time. They run in dirty, dusty and environments. They sit idle for months and months through the wintery snows and sweating heat of summer. Each of these situations require both specialized and non-standard maintenance cycles. Twin City Vibration and Balance can assist with ensuring that the grain and bin driers will continue to operate at peak efficiency for years to come.

Experience

Meet The Technician

Michael Jacobson, the founder of Twin City Vibration and Balance, is a United States Navy veteran. Completing 7 years of active duty and 3 years reserve before being honorably discharged. The next adventure was 5 years perusing a Mechanical Engineering Degree at South Dakota State University. After that I began my career in the fan industry. The next 16 years were spent with Twin City Fan and Blower in their assembly plant learning skills in quality control, machining, balancing, welding, painting and personnel management then later as the Senior Field Service Technician. As the Senior Service Technician, I had the opportunity to work on rotating equipment in nearly every industry, from IT to Aerospace to Health Care. Throughout my career in the fan industry, I have served in many roles at job sites including, a technical advisor, a trainer, and a quality control inspector to a laborer replacing bearings and a painter painting shafts. My monumental experience in every aspect of the rotating equipment industry makes me a trusted advisor in any situation that can arise with rotating equipment.

Certifications – OSHA-30-2020, Cat II, MSHA-2020, TWIC 2021 SKF bearing damage certificatios.

Licensed and bonded.

16 + years in the fan maintenance industry.

Talk With An

Expert Today!

Michael Jacobson

Owner / Analyst / Sr. Technician

763-219-3730

michael@tcvibe.com

Why Choose Twin City Vibration & Balance.

We Put Your Companies Rotating Assets First

At Twin City Vibration and Balance, we do not hold allegiance to a manufacturer and always have the best interests of the equipment in mind. We are also founded on a goal of improving the reliability of rotating equipment for everyone. To do this we have brought our cost within reach of small businesses.

16 + years of experience.

Customer-focused support tailored to your specific needs.

Affordable prices.

Top notch equipment and training.

We are always available to talk to our clients, ALWAYS.

These companies Called on our Senior Technician, Michael jacobson

to know the status of there machinery.

What Are You Waiting For.

3M Hutchinson

Allina Health

Ardagh Glass

Baldinger Bakery

BP

Cardinal Glass

Corning

Devils Slide

First Quality

Gallo Glass

GE

ICB Biofuels

John Deer

City of Henderson, NV WWTP

Crockett CO Generation

NEFCO

McCallistar College

Pioneer Seed

US Bank Plaza

370 Osborn building

LeSalle Plaza

New York State Moynihan Train Hall

New York State Battery Park

10900 Wayzata building

Presidio CA

McDonald & Owen

Campbell Tower

General Mills

AL-Corn

Bauer Built Tires

Chrysler, Ford and GM plants

Alaska Way Seattle, WA

Lockheed Martin,

Aruco

Eastman

Shell

The Skyscraper Center (701 Building)

East Michigan University

Verso / New Page

Temp Air